Products

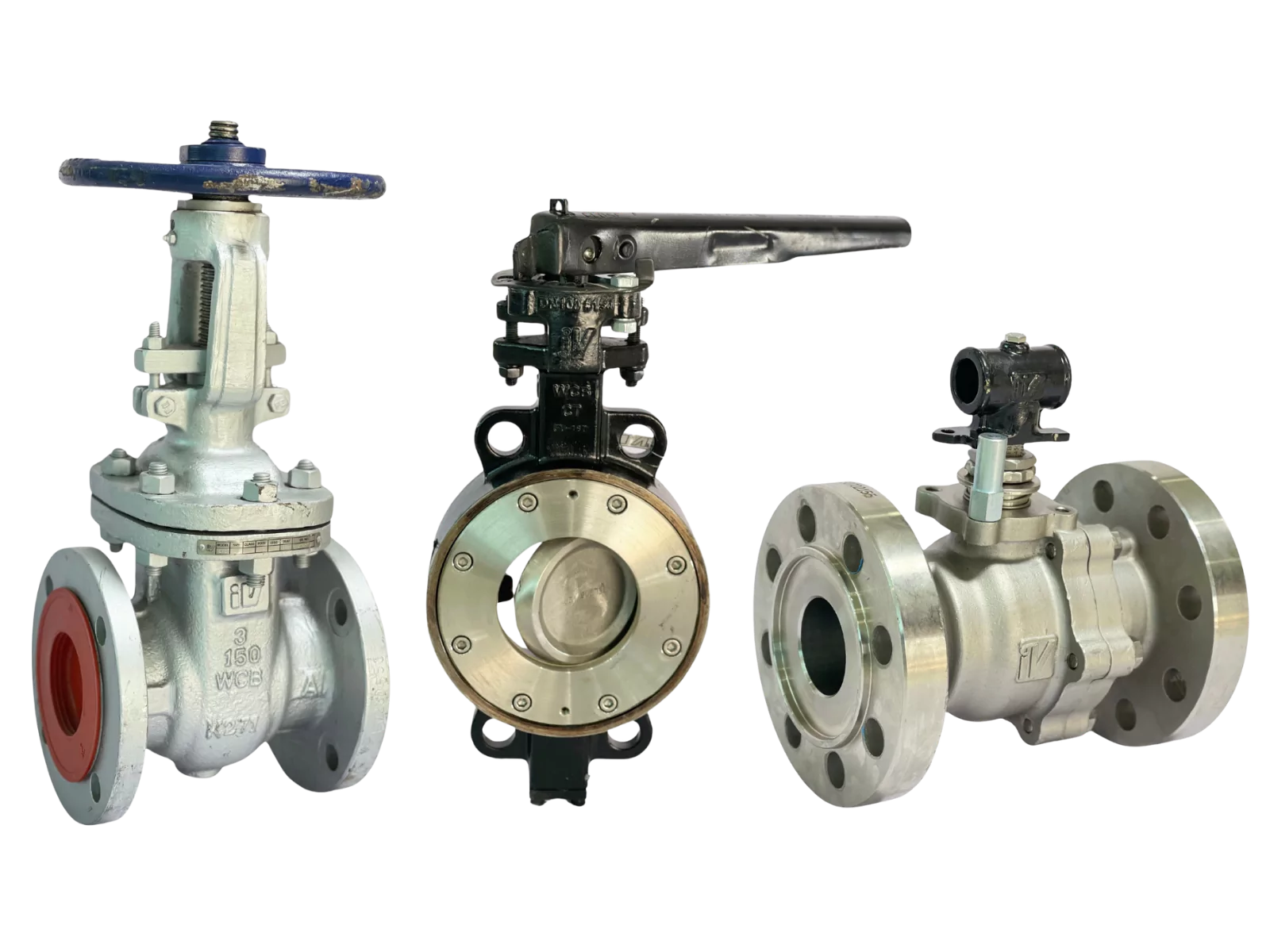

Metalic Valves

Shreeji’s Metallic Valves offer superior durability for demanding industrial environments. Our comprehensive range includes ball, gate, globe, and check valves engineered to withstand extreme conditions while ensuring reliable performance with minimal maintenance across chemical, petrochemical, and energy applications.

Business Partner

Ball Valves

Butterfly Valves

Resilient Seated Butterfly Valve

Resilient PTFE Seated Butterfly Valve

High Performance Butterfly Valve

Gate & Globe Valves

Swing Check Valve

Ball Valves

Floating Ball Valve

Floating ball valves are used in virtually every industry across the globe. ball valves are available in various optional trims and configurations including resilient seated, metal seated, and v ball control valve trims. Ball Valves feature a flexible design, offering exceptional value and dependable operation across various service conditions in a rugged flanged ball valve design.

- Designs – ASME B16.34, ISO 17292, API 6D, API 608

- Testing – API 598, EN 12266-1, ASME B16.34, API 6D, ISO 5208

- Construction – 2 Piece,

- Size Range – NPS ½ to 12 / DN 15 to 300

- Rating – ASME Class #150, #300, #600,

- Materials – WCB, CF8, CF8M, CF3, CF3M, CD4MCu, NICKEL etc,

- Seat Material – TFM, PTFE, RPTFE, PEEK, DEVLON, METAL TO METAL,

- End Connections – Flanged ASME 16.5, RF, RTJ, LFF,

- Certifications – API 607, API 6FA, ISO 10497, ISO 9001, PED, SIL, ATEX, API6D

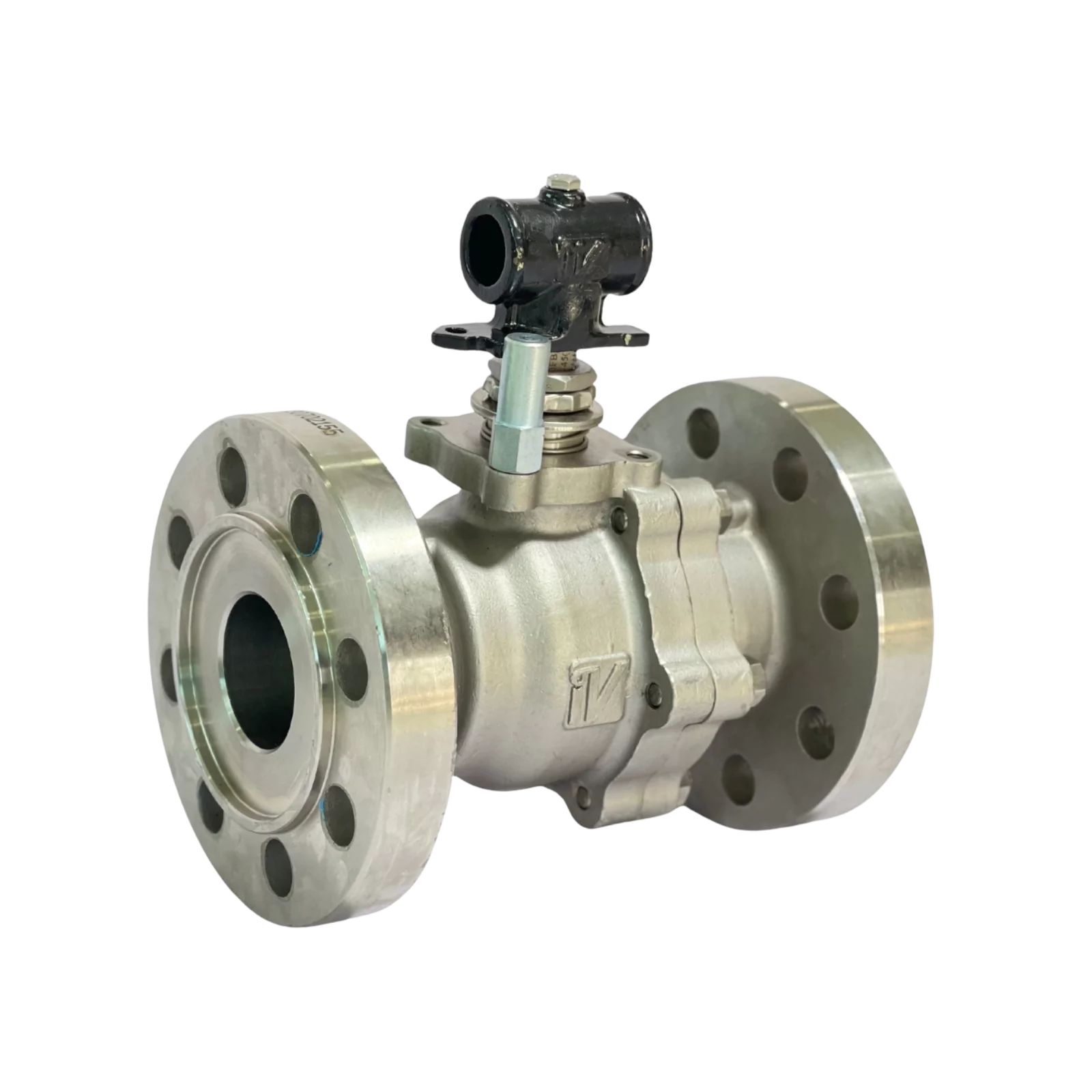

Trunnion Mounted Ball Valve

Ball Valves

Trunnion Mounted ball valves are based on a system that provides a fixed ball and floating seat rings, moving along the valve axis, The side load given by the pressure acting on the ball is absorbed by the bearings. At low pressure, the seat sealing is obtained by the spring action on the seat rings. The more the pressure increases, the more it pushes the seats against the ball.

- Designs – API 6D, API 608, ASME B16.34, ISO 17292

- Testing – API 6D, API 598, EN 12266-1, ISO 5208

- Construction – 2 Piece, 3 Piece

- Size Range – NPS ½ to 24 / DN 15 to 600

- Rating – ASME CLASS 150 to 2500

- Materials – A105, LF2, F304, F316, WCB, CF8M, CF3, CF3M, CD4MCu, NICKEL etc,

- Seat Material – TFM, PTFE, RPTFE, PEEK, DEVLON, METAL TO METAL,

- End Connections – Flanged, Butt Weld,

- Certifications – API 607, ISO 15848-1

- Fugitive Emissions – ISO 15848-1, ISO 15848-2

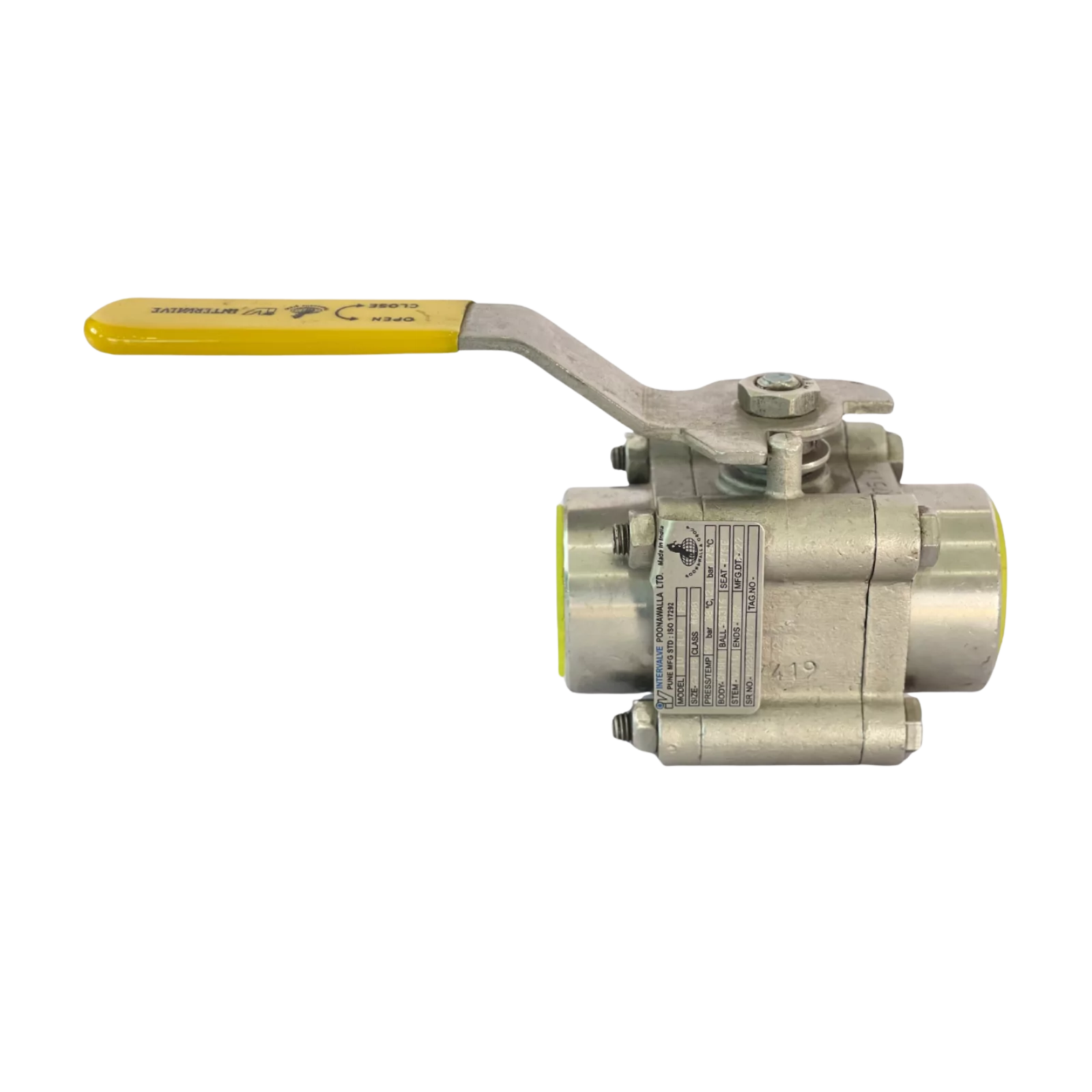

Forged Ball Valve

Ball Valves

The 3-piece design is available for various scheduled pipes. This type of construction is of swing-out design and easy inline maintenance. By removing body bolts & nuts the complete valve may be lifted out of the line or swing out by keeping one bolt. The valve can easily swing out of the line providing complete entry and fast disassembly or maintenance. The swing-away feature also maintains pipe alignment during inline maintenance. The 3-piece design offers the function of both valves as well as a union.

- Designs – EN-17292 / API-6D

- Testing – API 598, EN 12266-1, ISO 5208

- Construction – 3 Piece,

- Size Range – NPS ½ to 2 / DN 15 to 50

- Rating – ASME CLASS 600, 800 & 1500

- Materials – A105, F304, F316, SPECIAL GRADE,

- Seat Material – TFM, PTFE, RPTFE, PEEK, DEVLON, METAL TO METAL,

- End Connections – Screwed, Socket & Butt Weld Ends./Nipple Extn

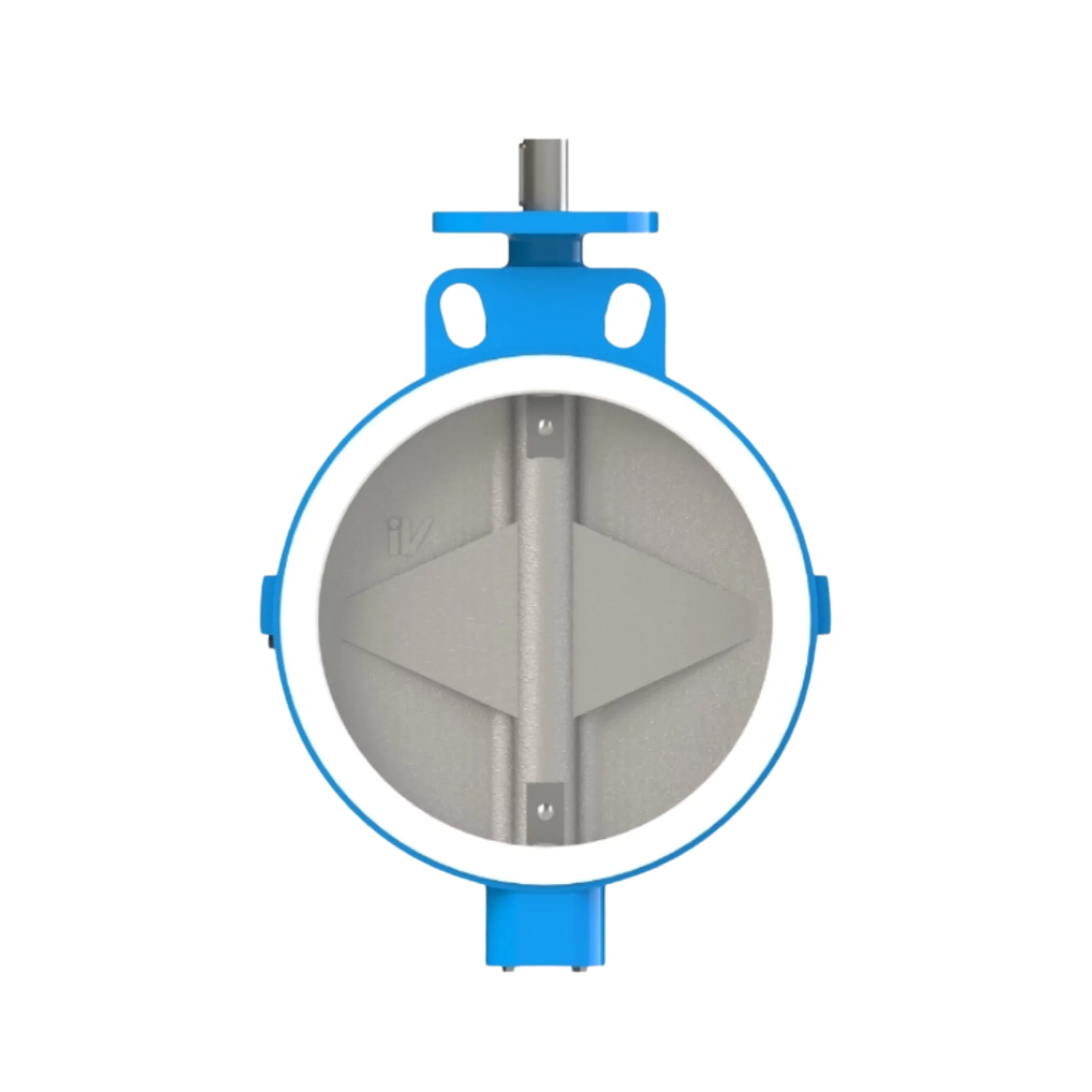

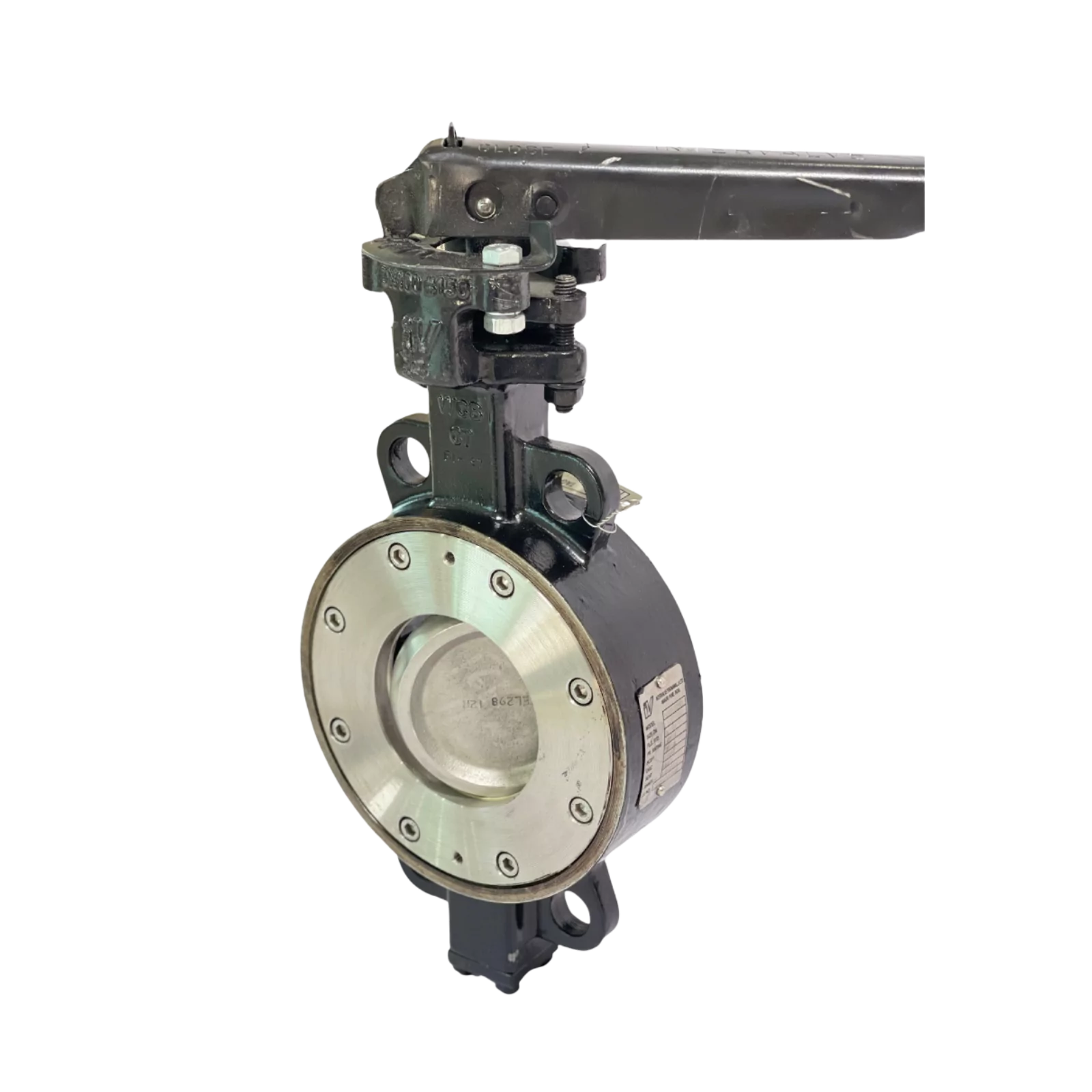

Resilient Seated Butterfly Valve

Butterfly Valves

The Rubber Seat Butterfly valve incorporates the optimum design features to provide long trouble trouble-free service in the field. This general purpose soft seated Butterfly valve has a fully rubber lined single piece body with centric disc construction and is available in wafer type body pattern.

The body liner which also functions as the soft seat, comes in either a replaceable version or an integrally molded (bonded) version and offers 100 % bi-directional sealing against vacuum to rated pressure of PN10 or PN16.

The wafer-style body has a universal design to fit between pipe flanges of almost all popular flange standards.

- Designs – API 609 category A / EN 593

- Valve Face to Face – API 609 category A / EN 593 Short wafer as per ISO 5752 Tab 5

- Testing – API 598 / EN 12261 Part 1

- Flange standard – Class 150, DIN EN 1092 – PN 6 / 10 / 16, JIS5K / 10K / 16K

- Construction – Centric Disc rubber-lined butterfly valve with a single-piece body.

- Size Range – DN 40 to 1200

- Rating – PN6, PN10, PN16

- Material Body – CI / SGI / WCB / CF8 / CF8M

- Material Disc – SGI / WCB / CF8 / CF8M

- Seat – EPDM / Viton / Nitrile / Neoprene / Hypalon / Silicon

- End Connections – Wafer Sandwiched with Semi Lug & Full Lug

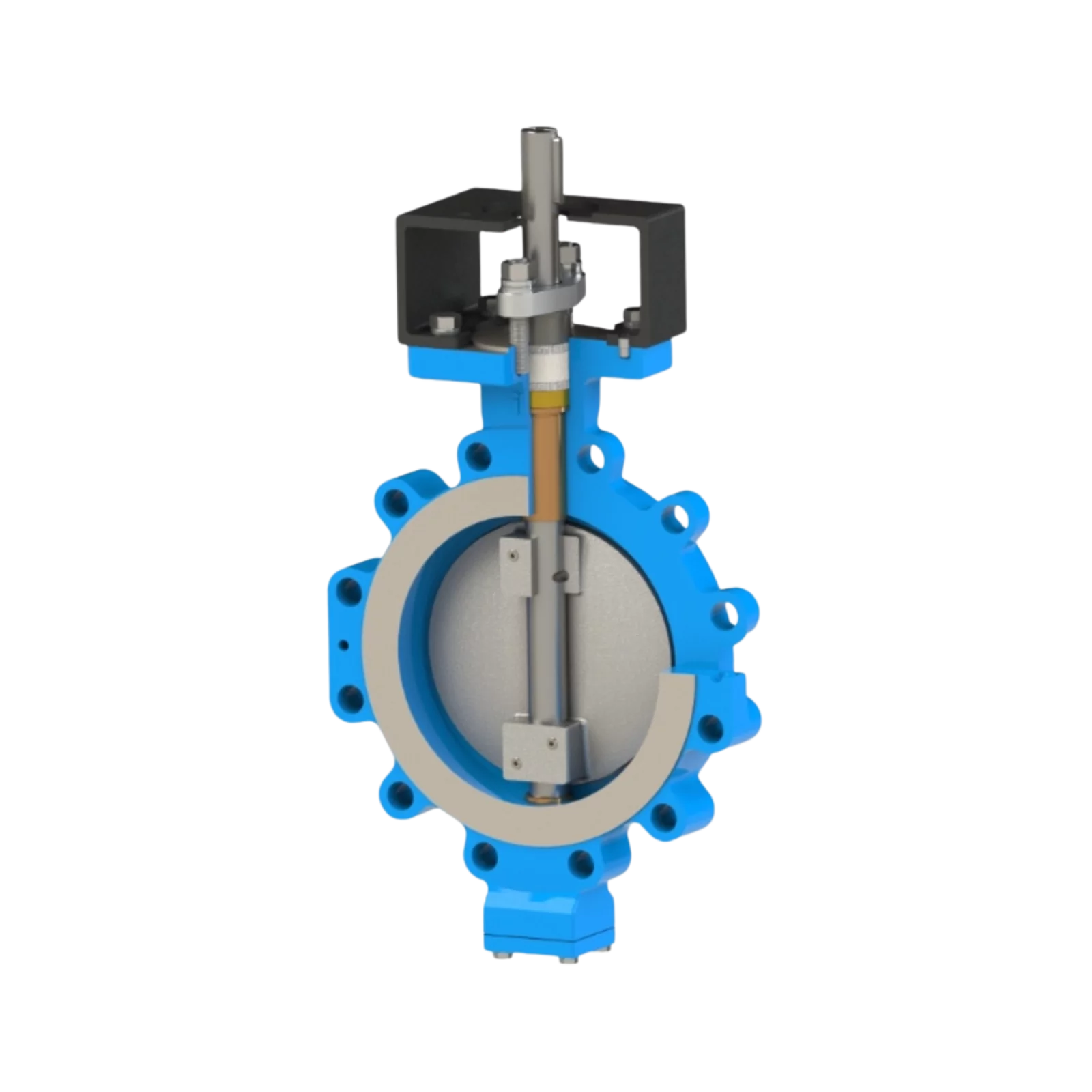

Resilient PTFE Seated Butterfly Valve

Butterfly Valves

PTFE lined Butterfly valve model IVTFE provides an optimum solution to the corrosion problems encountered by the chemical process industries with conventional Butterfly valves. The PTFE seat liner covers the entire wetted surface of the body and extends onto the flange contact faces, thus eliminating the possibility of any media contact with the body metal.

The circularly moulded full backup elastomer and live-loaded disc shoulder sealing ensure bubble-tight closing of the Valve with zero shaft leakage. The valve is adaptable for ON / OFF as well as control duty and can be fitted with actuators and accessories as required to meet the specific duty conditions.

- Designs – EN 593

- Valve Face to Face – EN 593 / ISO 5752 Tab 5 & API 609 category A

- Testing – API 598 / EN 12261 Part 1

- Flange standard – Class 150, DIN EN 1092 – PN 6 / 10 / 16, JIS5K / 10K / 16K

- Construction – Centric Disc Butterfly valve with PTFE-lined body

- Size Range – DN 50 to 350

- Rating – PN10,

- Material Body – SGI / WCB / CF8 / CF8M / Other special alloys

- Material Disc – SGI / WCB / CF8 / CF8M / Other special alloys CF8M

- Seat – PTFE/RPTFE

- End Connections – Wafer Sandwiched with Semi Lug & Full Lug

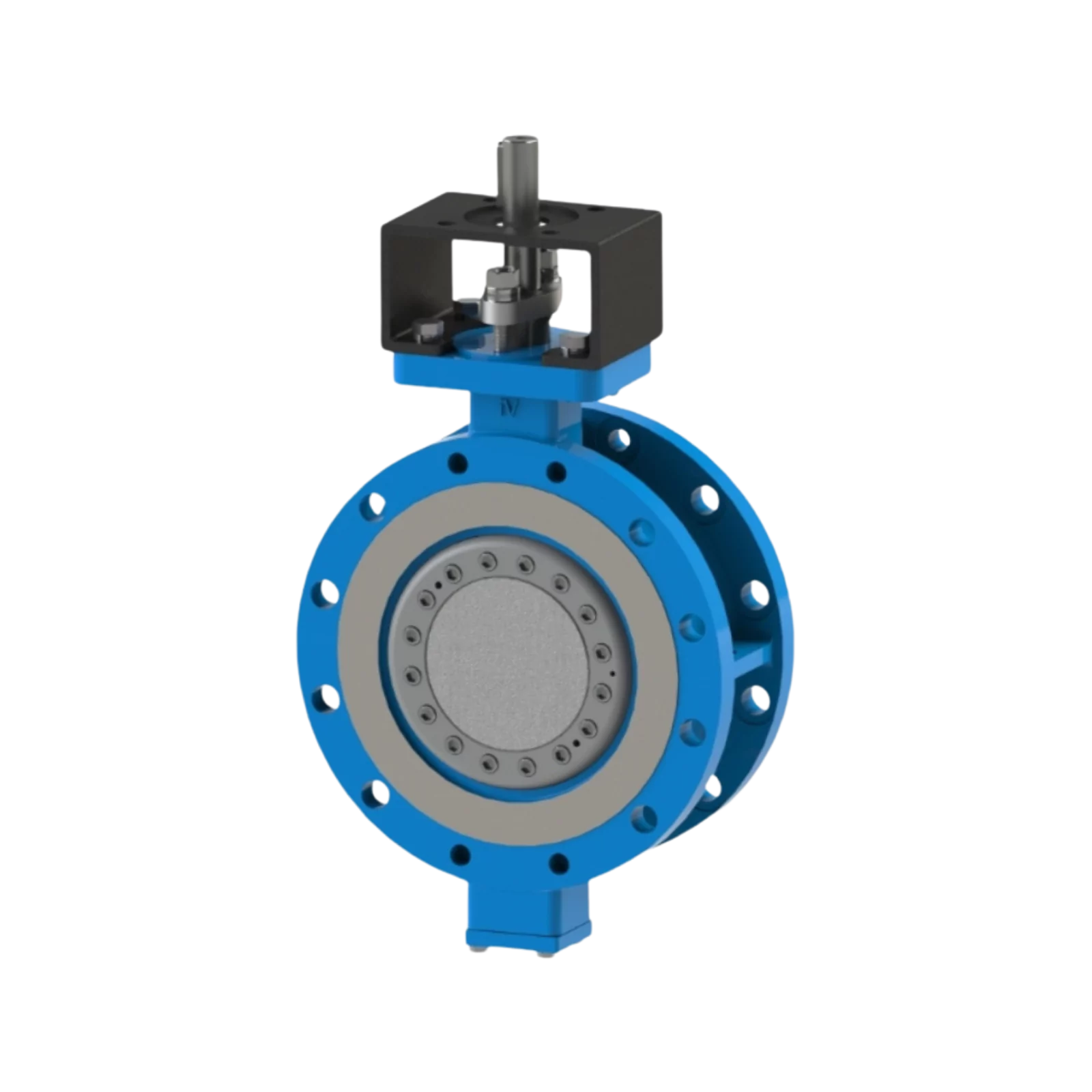

High Performance Butterfly Valve

Butterfly Valves

The ultimate in high-performance Butterfly valves, IV’s IVEX – series incorporates the ‘state of the art’ valve technology to outperform the competition. The double offset disc design nearly eliminates the seating wear due to the camming action of the disc during closing. The mechanical stopper provided on the valve body ensures precise valve closing every time to ensure specified seat tightness. The disc has a spherical profile and comes out of contact with the seat in the initial opening itself.

The valve is available with 3 distinctly different seat design versions, viz. Soft seated, Fire safe and Metal to Metal seated with wafer or wafer lugged body option.

- Designs – API 609 category B

- Valve Face to Face – API 609 category B / ASME B 16.10

- Testing – API 598 / FCI-70-2

- Flange standard – ASME B 16.5 Class 150

- Construction – Double offset Disc Design High-Performance Butterfly valve, IVEX-F – Fire safe seat version, IVEX-T – Soft seated PTFE or RPTFE seat version, IVEX-M – Metal to metal seated version

- Size Range – DN 50 to 600

- Rating – ASME class 150,

- Material Body – WCB / CF8/ CF8M / DUPLEX SS / AL. BRONZE / Other special alloys

- Material Disc – WCB / CF8/ CF8M / DUPLEX SS / AL. BRONZE / Other special alloys

- Seat – PTFE/RPTFE & Metal to Metal

- End Connections – Wafer sandwiched or Wafer lugged

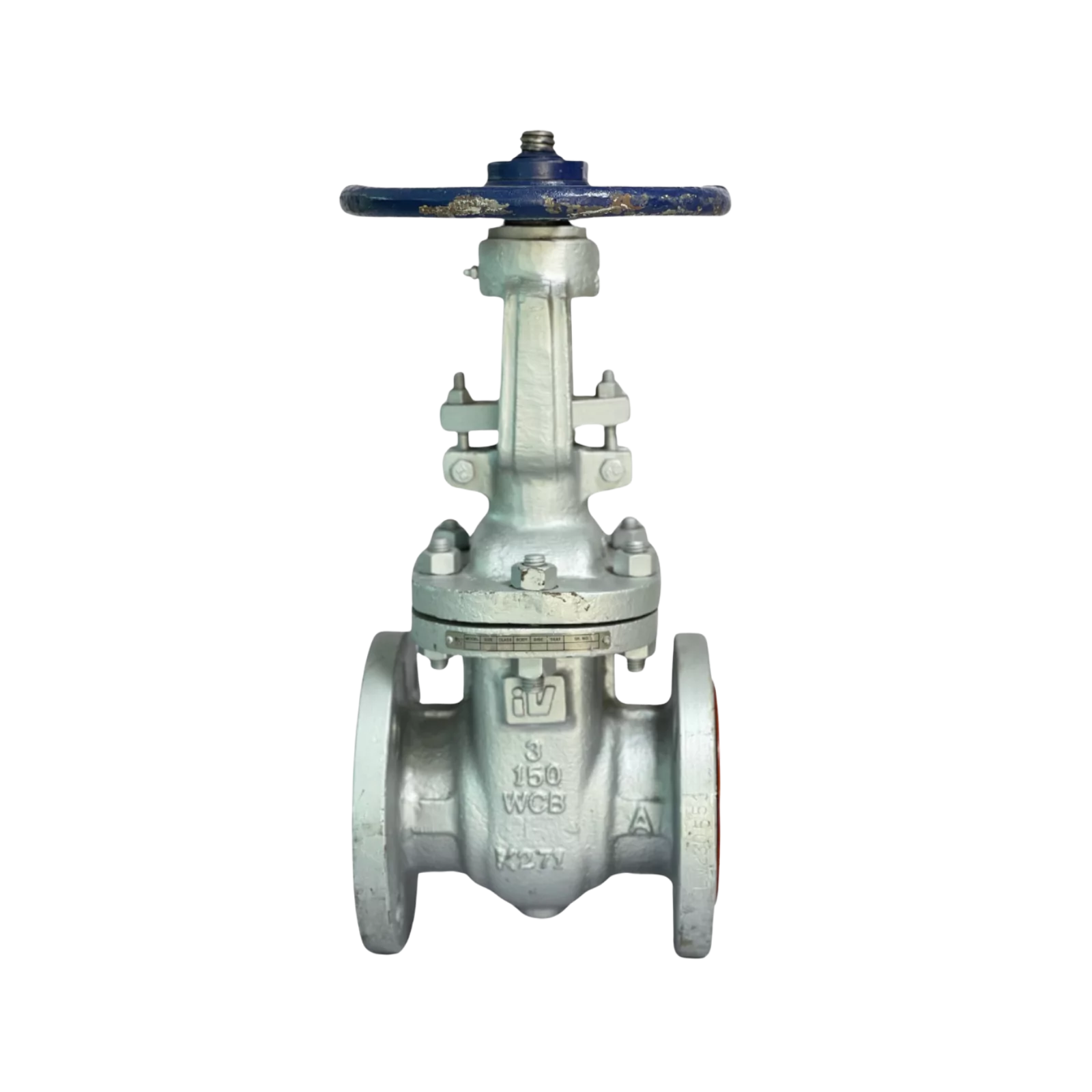

Gate Valve

Gate & Globe Valves

Gate valves incorporate state of the art design features to provide a rugged construction, reliable operation and long life. The valves are suitable for normal services to most demanding applications covering all segments of the process industries including oil & gas, refineries, petrochemicals, pharma, steel, alumina power plants and common utilities. An ideal valve for the flow isolation and ON / OFF duty. Our valves can be provided with special features like water sealed gland for vacuum service, bypass arrangements for pressure balancing, special cleaning for oxygen service, multi-start spindle for low-effort operation, extended spindle/bonnet for pit-mounted / low-temperature service & NACE compliant materials for sour service in petroleum industries, etc.

- Designs – ASME B16.34 / API 600 / IBR

- Valve Face to Face – ASME B16.10 (upto 36″)

- Testing – API 598 / EN 12266 PART 1 (BS 6755 PART 1)

- Flange standard – ASME B16.5 (up to 24″) / ASME 16.47 (above 24″)

- Construction – Outside screw & yoke (OS & Y) construction.

- Size Range – DN 50 to 750

- Rating – ASME Class #150, #300, #600, #900,

- Material Body – WCB, LCB, WC6, WC9, CF8, CF8M etc. / Other special alloys

- Trim – 1, 2, 5, 8, 10, 12, 16 etc.

- End Connections – Flanged

Globe Valve

Gate & Globe Valves

Globe valves incorporate state-of-the-art design features to provide a rugged construction, reliable operation and long life. These valves are suitable for normal services to most belligerent applications covering all segments of the process industries including oil & gas, refineries, petrochemicals, fertilizers, power plants and common utilities. An ideal valve for the flow isolation as well as flow regulation duty. Our valves can be provided with special features like water sealed gland for vacuum service, bypass arrangements for pressure balancing, special cleaning for oxygen service, multi-start spindle for low-effort operation, extended spindle/bonnet for pit-mounted / low-temperature service & NACE compliant materials for sour service in petroleum industries, etc.

- Designs – ASME B 16.34 / BS1873 / IBR

- Valve Face to Face – ASME B 16.10 (up to 18″)

- Testing – API 598 / EN 12266 PART 1 (BS 6755 PART 1)

- Flange standard – ASME B16.5

- Construction – Outside screw & yoke (OS & Y) construction.

- Size Range – DN 50 to 450

- Rating – ASME Class #150, #300, #600, #900,

- Material Body – WCB, LCB, WC6, WC9, CF8, CF8M etc. / Other special alloys

- Trim – 1, 2, 5, 8, 10, 12, 16 etc.

- End Connections – Flanged

Forged GGC Valve

Gate & Globe Valves

Forged Gate, Globe & Check valves incorporate state-of-the-art design features to provide a rugged construction, reliable operation and long life; suitable for all the segments of the process industries including chemical, petrochemicals, pharma, steel, alumina, power plants and common utilities. The valves are available in Socket weld, Screwed end, Butt weld & Flange end connections. Valves can be provided with special cleaning for oxygen service, NACE Compliant materials for sour service in the petroleum industries etc. The valves can be provided with a motor operation for Gate & Globe valves wherever required.

- Designs – ASME B16.34 / API 602 / ISO 5352 / IBR

- Valve Face to Face – ASME B16.11

- Testing – API 598 / EN 12266 PART 1 (BS 6755 PART 1)

- Construction – Outside screw & yoke (OS & Y) construction (for gate & globe valve).

- Size Range – DN 15 to 50

- Rating – ASME Class #800, #1500, #2500,

- Material Body – WCB, LCB, WC6, WC9, CF8, CF8M etc. / Other special alloys

- End Connections – Socket Weld, Butt Weld & Welded Flanged

Swing Check Valve

Swing Check Valve

Swing Check Valves offer the optimum solution for backflow prevention in liquid and gas lines. Our special design feature provides a rugged construction, reliable operation and long service life. The valve finds applications in various segments of the process industries covering chemical, petrochemicals, pharma, steel, alumina, power plants and common utilities. The design offers a low-pressure drop operation, which makes the valve more energy-efficient. Pressure-sealed bonnet design is incorporated for high-pressure applications for reliable sealing. The valve can be provided with an external dashpot arrangement to provide non-slam operation, ideal to prevent water hammer.

- Designs – ASME B16.34 / BS 1868 / IBR

- Valve Face to Face – ANSI B16.10 (up to 24″)

- Testing – API 598 / EN 12266 PART 1 (BS 6755 PART 1)

- Construction – Swing Type with Bolted Bonnet

- Size Range – DN 50 to 600

- Rating – ASME Class #150, #300, #600, #900,

- Material Body – WCB, LCB, WC6, WC9, CF8, CF8M etc. / Other special alloys

- End Connections – Flanged

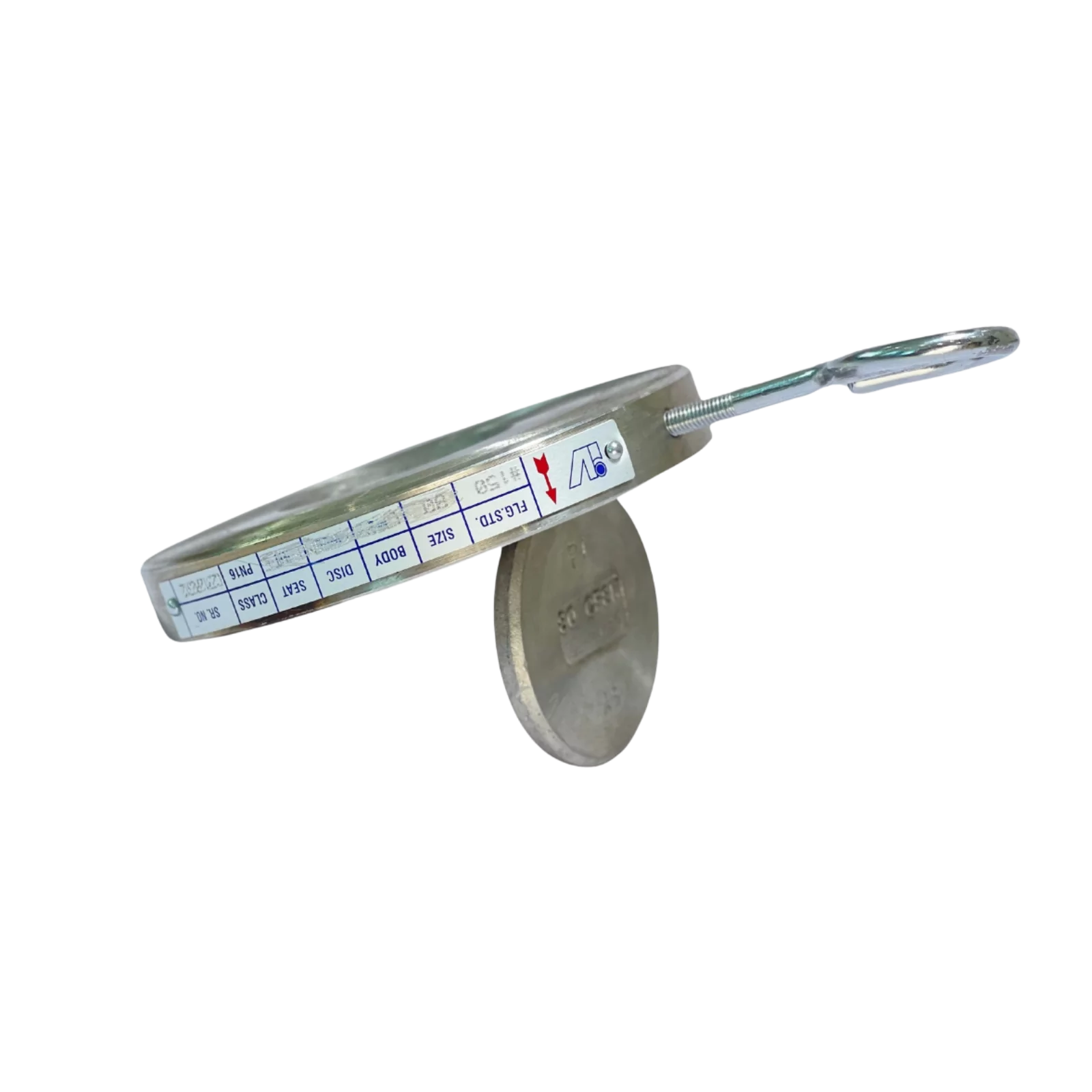

Wafer Check Valve

Swing Check Valve

Wafer Check Valve Models IVC and IVCT are primarily single plate swing check valves with a short pattern wafer body conforming to the API6D and ASME B16.10 face-to-face dimensions. The valve has a simple but reliable and robust construction. The low inertia disc design enables the valve to open or close with a very low differential pressure which makes them ideal for services operating under low differential pressures. The valve is ideal for pump discharge duties. The eccentric mounted hinge pin in combination with the disc seat guarantees a positive shut off of the returning media.

- Designs – API 6D / ASME B 16.10

- Valve Face to Face – ASME B 16.5 #150, DIN EN 1092-PN10 & PN16 BS 10 Table D & E

- Testing – API 598

- Construction – Short pattern wafer type, Single plate check valve.

- Size Range – DN 25 to 900

- Rating – PN16, PN10,

- Material Body – SGI / WCB / CF8 / CF8M / CS – I2062 / Other special alloys

- Seat – EPDM / Viton/ Nitrile/ Neoprene / Hypalon / PTFE or GFT

- End Connections – Wafer Sandwiched

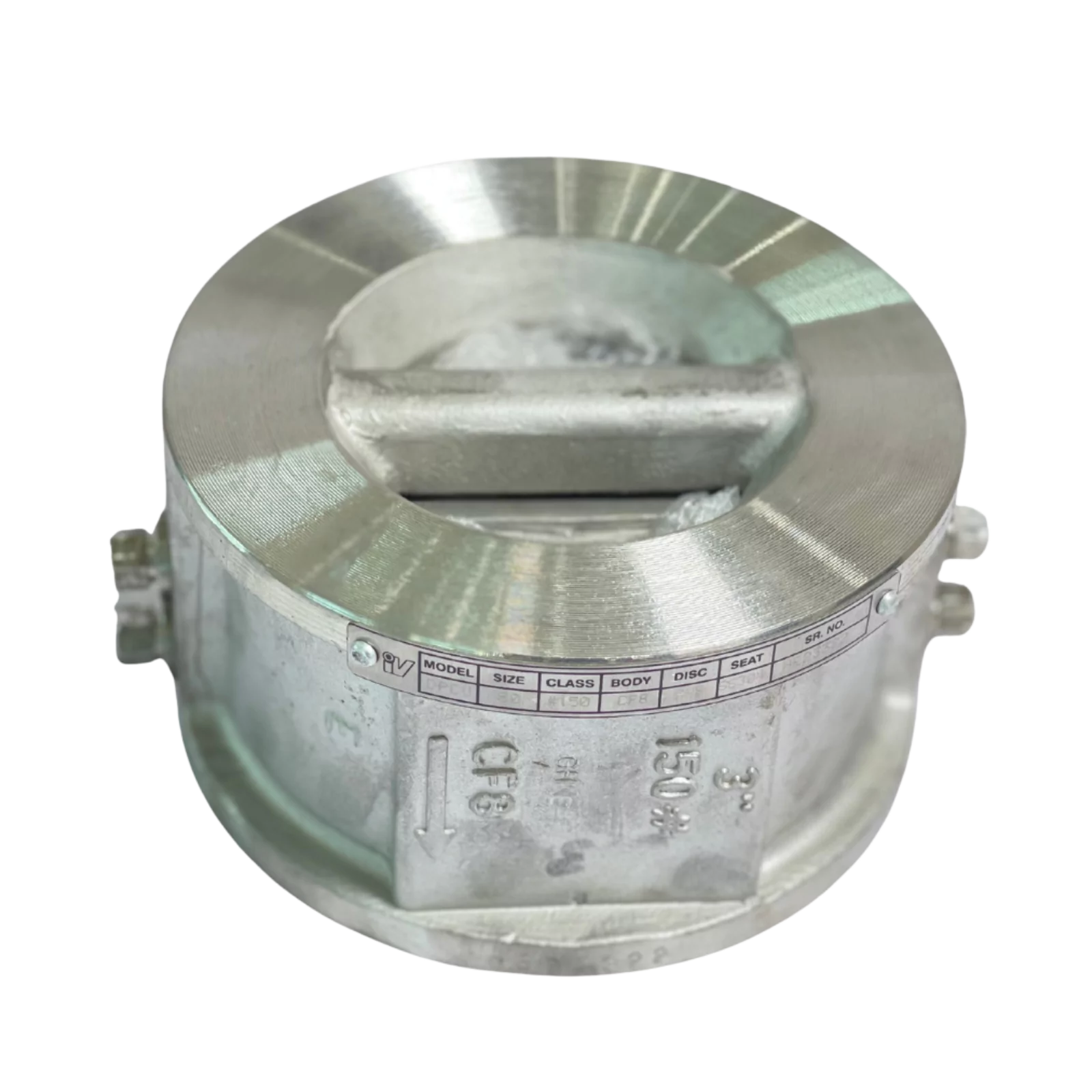

Dual Plate Check Valve

Swing Check Valve

Spring Loaded Dual Plate check valve uniquely designed for applications. The constructional feature makes the valve much smaller in size, lighter in weight & makes it much feasible in operation as compared to conventional swing check valve, valve employs dual spring loaded plates/disc hinged on a central hinge pin. It operates on the differential pressure between fluid flow pressure & spring torsion pressure. As the flow pressure reduces, the plates tend to close with a cushion effect by spring torsion force thereby restricting the reversal of fluid flow.

- Designs – ASME B16.34 / API 594

- Valve Face to Face – API 594

- Testing – API 598 / EN12266 Part 1

- Construction – Dual Plate Check Valve

- Size Range – DN 50 to 600

- Rating – ASME Class #150, #300, #600, #900,

- Material Body – WCB, LCB, WC6, WC9, CF8, CF8M etc. / Other special alloys

- End Connections – Wafer Sandwiched